iCut 3.6 Self-propelled robotic mower

Ferri remote controlled device

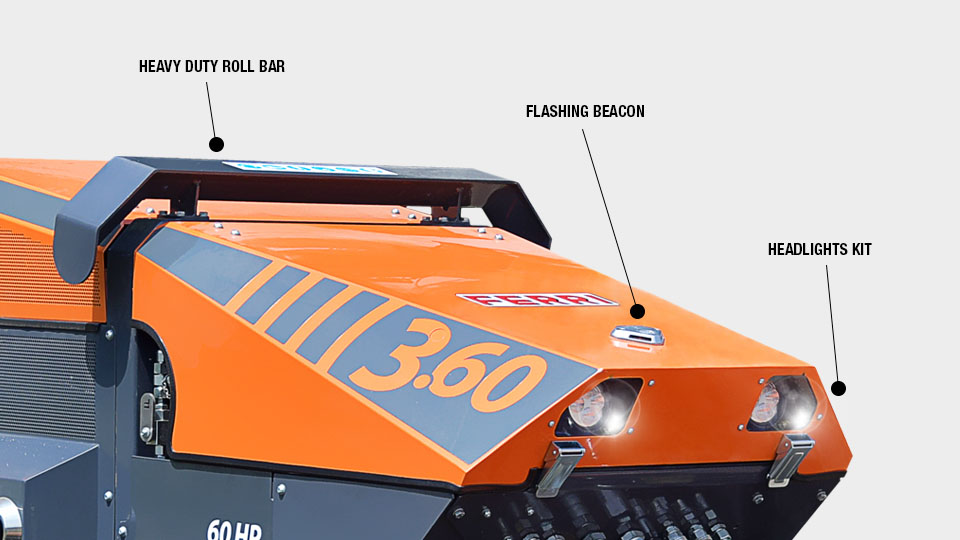

The new iCut 3.60 offers high performance, along with a large operating range and easy maintenance.

The iCut 3.6 self-propelled robotic mower is intended for mowing grass, weeds, bushes and branches. The mower ensures maximum safety in critical and difficult conditions and achieves top performance. iCut 3.6 allows the user to work in full compliance with safety standards and health and safety regulations, while cleaning hard-to-reach places.

Two large joysticks allow precise control of movement, steering and head height. The simple control layout, which allows starting, adjusting the speed and sensitivity of the control according to personal preferences, enables productive and safe work in all working conditions.

In addition, the console has many other functions on the instant stop button, such as coolant and oil temperature indicators, radio control battery functions, engine oil pressure, fuel level indicator, air filter clogging indicator, cruise system on/off, driving speed (slow /fast) and turning on the return fan.

The 3-cylinder turbo intercooled Hatz 3H50 and 60 hp (43.39 kW) 1,464 cc engine provides maximum torque from 1620 to 2060 rpm. The new engine is fully compliant with the new anti-pollution directives (STAGE V – CERTIFIED). The engine is elastically fixed to the chassis with the help of optimized and improved silent blocks with functions to contain all the vibrations produced and especially lateral vibrations.

Cooling is liquid and uses the extremely reliable FLEXXAIRE system with automatic and manual hydraulically controlled reversible fans. This cooling system keeps the radiator clean, increases engine performance and consequently reduces fuel consumption.

Completely new diagnostics enable automatic and immediate identification of the type of failure and identification of corrective maneuvers. For an additional form of support, standard is the use of a Murphy Chart device, which allows reading of diagnostic information of the powertrain. In this way, everyone has the opportunity to recognize the current problem and decide on the optimal solution, and the large screen allows insight into all vital iCut information.

Optimal weight distribution and a low center of gravity mean that the iCut 3.6 self-propelled mower is capable of working on slopes of up to 55° in all directions, while providing optimal traction in all working conditions. In extreme working conditions, when it is necessary to increase the safety of the machine, it is possible to increase the width of the chassis with a hydraulic cylinder and thereby increase the total width of the tracks.

When it is necessary to change the width of the chassis for greater traction with the ground, the operation of changing the width of the chassis from 132 to 167 centimeters is carried out directly from the radio control in a few seconds.

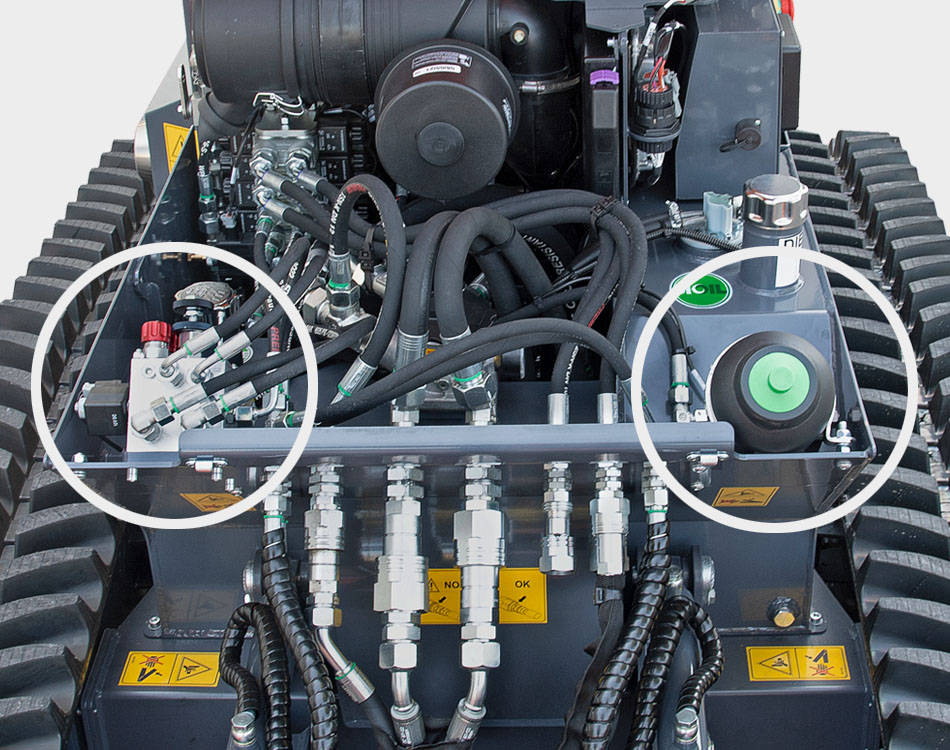

The automatic track tensioner allows you to be sure that the tracks are always operating at the tension provided by FERRI, which is synonymous with reliability and high performance, and simplifies track replacement procedures. The system consists of a hydraulic valve assembly that ensures a long service life of the track and components even in the most difficult working conditions.

Three different types of tracks are available to operate in all types of working conditions with the highest level of safety and regulatory compliance:

EXTREME

Rubber tracks with a deep profile. These tracks are ideal for working on moderately steep slopes as they minimize damage to the lawn.

GRIP

Rubber tracks with steel studs provide maximum traction on rocky terrain or uneven ground that could damage the rubber.

GRIP PLUS

Tracks with steel wedges and studs for use in extreme conditions, both in terms of slope and type of terrain, where high layer resistance and high capacity for working on slopes are required.

Hydraulic mower heads R1300-RH1600

We recommend them for mowing grass, weeds and bushes. They have two working widths, 130 and 160 cm, which allow you maximum productivity.

Hydraulic forestry head RF-R 1300

The forestry mulcher model RF-R has increased the robustness of its construction, as well as durability and impact resistance, with an improved design.

The use of DOMEX700 material for the inner subframe allows the construction to be light but very strong and resistant.

The iCut 3.6 self-propelled robotic lawnmower increases the availability of equipment and enables year-round use. Thanks to the various attachments specially designed for iCut, this machine is suitable for use in forestry, maintenance of public and private green areas, gardening, winter road maintenance and material handling.

The mowing head lateral movement kit (optional) available for the R1300 mowing head, with its 20+20 centimeter movement, allows you to reach working areas that are otherwise impossible to work on, such as river banks, canals, etc.

The new hydraulic/pneumatic floating system is the result of almost 10 years of Ferri experience and allows the use of equipment of various weights and sizes while maintaining optimal balance of the machine and equipment assembly thanks to the valve unit/accumulator assembly. In practice, it allows the equipment used to follow the direction of the ground perfectly, while reducing friction and at the same time avoiding harmful loads on the iCut lifting arms.

The optional use of CEJN Multi-X couplings offers the advantage of saving time when connecting or disconnecting equipment, as multiple hydraulic lines are bundled together and can be operated with a single connection. Practicality and simplicity suggest their use in the case of rapid successive use of several pieces of equipment.

We are aware that only quick and professional assistance ensures efficient work with our products. Therefore, we pay great attention to after-sales cooperation. A well-equipped service department ensures that your work runs smoothly in all seasons. In winter, we provide you with 24-hour assistance and offer help even in the most difficult conditions.